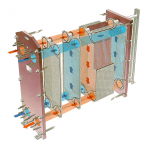

Gasketed Plate Heat Exchangers

Sol-Tech srl Solution Technology can provide a wide range of inspectionable plate heat exchangers for many different types of application. Our solutions stand out for their great flexibility, which makes it possible to design and build inspectionable exchangers that are perfectly suited to the applications they are meant to serve.

WE CAN PROVIDE DIFFERENT KINDS OF PLATE HEAT EXCHANGERS, SUCH AS:

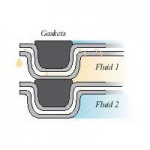

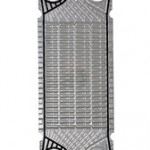

- gasketed plate heat exchangers The plates can be of the traditional H-L-M undulated type with very high efficiency and performance and with dedicated solutions for the oleodynamic sector (SAE flanges), or with channel undulations more suited to gas and fluids with a low charge loss. This kind is particularly suited for use with condensation.

- semi welded plate exchangers The semi-welded exchangers are mainly used for applications such as ammonia, or with fluids that cannot come into contact with the gaskets. These exchangers, for both symmetrical and asymmetrical flow rates, are welded in couples so they generate a safety channel without the possibility of opening. The couple of plates is laser welded in order to create a channel for the ammonia or other particular liquids. The gaskets around the holes are double and arranged on either side of both the inlet and outlet hole, which means that a maximum safety area is created around the connections.

- wide gap – free-flow plate exchangers. The particular feature of the wide gap exchangers is having plates with points of contact but channels up to 12 mm while the Free Flow exchangers are without points of contact. Both are best used for processes where the fluids are not clean and have both organic and inorganic impurities.

- Double wall plate exchangers The double wall plated exchangers work in the same way as the traditional exchangers. The difference compared to the traditional ones is that each plate is made up of two identical plates which are laser welded around the four holes. This provides a double protection against any possible mixing of the fluids in the event of leaks. Typical applications are: pharmaceutical industry, food industry, district central heating, transformer oil cooling, etc.

ADVANTAGES OF SOL-TECH SRL SOLUTION TECHNOLOGY

Thanks to the long-standing experience acquired through contact with the many and varied needs of the different applications for which plate exchangers can be used in the various sectors, with our inspectionable plate heat exchanger solutions one can:

- Have the maximum construction flexibility in one’s desired exchanger which, being built on the basic principle of the model, can be built in many combinations of frame, plate and connections.

- Adapting inspectionable exchangers to the most diverse applications, using different kinds of plates.

- Maximum optimization of the sizing and accurate performance calculations for the heat exchangers.

- Be supported by a consultancy service for one’s own applications, from the initial choice of the kind of exchanger to the maintenance of installed exchangers.

ADVANTAGES OF INSPECTIONABLE PLATE HEAT EXCHANGERS

The Inspectionable plate heat exchangers compared to other types of plate heat exchangers (e other types of heat exchangers), offer the following advantages:

- Are easy to dismantle for inspection, cleaning and maintenance.

- Can be easily expanded and adapted, with the possibility of adding or replacing plates if the operating conditions change.

- They require a less intensive maintenance thanks to the high average useful life of the gaskets and the ease of any replacements which may be necessary.

- They reduce the risk of service failures due to extended operation breakdowns.

Furthermore, like the other types of plate exchangers the Inspectionable exchangers can provide:

- An effective heat transfer

- As they are countercurrent flow heat exchangers they have much higher heat exchange coefficients compared to concurrent exchangers

- Very compact size which results in a saving of space.

- High turbulence which reduces the soiling effect and improves thermal efficiency

- Ease of transportation and installation

TECHNICAL SPECIFICATIONS OF THE INSPECTIONABLE PLATE HEAT EXCHANGERS

Here are a few technical details on our inspectionable plate heat exchangers

| Range of flow rates | Operating pressure | Operating temperature |

| 0 – 4600 m3/h | 10 – 25 bar | -40°C – + 180°C |

| Pressure | Temperature | Connections |

| 10 – 25 bar | – 40°C – + 180°C | DN25- DN500 Flanged, to be welded and threaded |

| Materials used for inspectionable heat exchanger plates |

Materials used for inspectionable plate heat exchanger gaskets |

| AISI 304 | NBR |

| AISI 316 | EPDM |

| AISI 316 | FPM |

| TITANIUM | FLUORINE RUBBER |

| TITANIUM/PALLADIUM | FLUOR G |

| AVESTA 254 SMO | SILICON |

| HASTELLOY C 276 | PTFE |

| INCONEL | – |

| MONEL | – |

FLUIDS

The plate heat exchangers can perform their task as an exchange between fluids and fluids/gases, condensers and evaporators with different fluid and fluid/gas combinations: water-water, water-air, water-vapour, air-air, water-oil and all the fluids and gases used in industrial processes.

If you are interested in our gasketed plate heat exchangers solutions you may contact us using the form contact us or by calling348 6925260.

English

English