Spiral Plate Heat Exchangers

Sol-Tech srl Solution Technology makes spiral plate heat exchangers customized to fulfil the needs of the particular application for which they must be used, both in terms of the construction of each exchanger and the materials to be used for their construction.

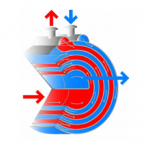

Each spiral exchanger is the result of a process that is as simple as it is sophisticated: a series of spacers are welded onto two or four sheets of metal which are then wrapped around a cylinder, thus creating two or four identical channels with a single passage; the concentric shape of the spacing and the internal threaded stud generate turbulence even at low Reynolds numbers.

ADVANTAGES OF SPIRAL PLATE HEAT EXCHANGERS

The spiral heat exchangers compared to other types of plate heat exchangers have a number of strong points:

- Reduced soiling

- Extremely compact size

- Ease of transportation and installation

- Extreme toughness

- Reduction of maintenance costs

- Great flexibility

- High exchange coefficients: seeing as they are countercurrent flow heat exchangers they have much higher heat exchange coefficients compared to concurrent exchangers

The spiral plate exchangers can be used for various different kinds of applications, particularly in industrial sectors, and can be used as heaters, coolers, condensers and evaporators.

This kind of exchanger is particularly suited for processing of very dirty liquids, loaded with fibres, residue and sludge, but also where condensation or evaporation is needed with low load loss.

- Project pressure

- In a vacuum – 60 barg

- Project temperature

- 100°C + 450°C

Fluids

The plate heat exchangers can perform their task as an exchange between fluids and fluids/gases, condensers and evaporators with different fluid and fluid/gas combinations: water-water, water-air, water-vapour, air-air, water-oil and all the fluids and gases used in industrial processes.

ADVANTAGES OF SOL-TECH SRL SOLUTION TECHNOLOGY

Creating your spiral plate heat exchangers with us to suit your application, means being able to rely on:

- Quality advice on the choice of materials and the construction process of the exchangers.

- The possibility of producing made to measure spiral plate heat exchangers

- Maximum optimization of the sizing and accurate performance calculations for the heat exchangers.

- Greatest optimization of the heat exchange based on the chosen configuration.

If you are interested in our inspectionable plate heat exchanger solutions you may contact us using the form contact us or by calling 348 6925260.

English

English